Arm Length:2,400mm & 6,600mm

Max Load Capacity:12kg & 6kg

Speed:3 m/s & 2.5 m/s

Reach:1,400mm & 1,300mm

Precision:±0.05mm & ±0.03mm

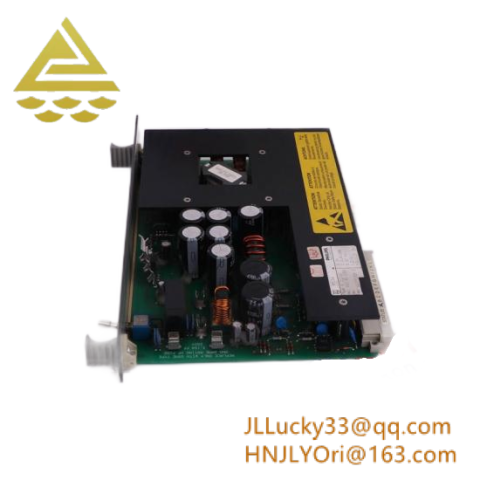

Control System:ABB IRC5 Compact Controller

Software Interface:ABB RobotStudio

Electrical Power:Single phase, 220V AC

The ABB IRB 2400 robot arm is engineered for optimal performance in high-speed assembly and material handling tasks. With its compact design and high-speed capabilities, it efficiently handles complex operations in tight spaces, enhancing productivity and reducing cycle times.

Featuring an advanced IRC5 Compact controller, the IRB 2400 offers unparalleled control and precision, enabling seamless integration into existing production lines. Its user-friendly interface simplifies programming and maintenance, making it accessible to operators of varying skill levels.

The ABB IRB 660, on the other hand, is designed for larger-scale applications requiring greater load capacity and reach. Its longer arm length and higher load capacity make it ideal for heavy-duty tasks in expansive manufacturing environments, ensuring robust and reliable operation under demanding conditions.

Both models benefit from ABB’s proprietary software, RobotStudio, which allows for detailed simulation and virtual commissioning, streamlining the setup and testing phases. This software facilitates efficient workflow optimization and error-free robotic operation.

Crafted with durability and reliability at its core, the ABB IRB 2400 and IRB 660 robot arms are built to withstand the rigors of continuous industrial use, offering low maintenance requirements and extended service life. These robots are equipped with safety features that comply with international standards, ensuring workplace safety.

In summary, the ABB IRB 2400 and IRB 660 robot arms represent a significant advancement in industrial automation technology, delivering superior performance, enhanced productivity, and exceptional reliability in a wide range of applications.

There are no reviews yet.